Specifications

Cutting Area:1500*3000mm

Cutting Speed:0-40000mm/min

Graphic Format Supported:AI, DWG, DXF, DXP, PLT

Application:Laser Cutting, Advertising industry,Machinery parts

Condition:New

Cutting Thickness:Materials

CNC or Not:Yes

Cooling Mode:Water Cooling

Control Software:Cypcut

Place of Origin:Anhui, China (Mainland)

Certification:CCC, CE, ISO

Warranty:1 Year

Control system:Shanghai CYPCUT system

Fiber Power Source:300W/550W/1000W

Cutting thickness:0.2-6mm depends

Cutting material:steel, SS, aluminum,,galvanized sheet

Cutting speed:0-5000mm/min

Consumable Parts:Nozzles and Mirrors

Motors and Drivers:Japan Servo System

Key Word:1.5kw fiber laser cutting machine

Features

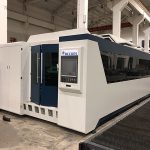

New product large scale heavy metal steel 1.5kw fiber laser cutting machineIt is widely used for carbon steel, stainless steel, aluminum and other metalmaterials cutting and forming, with high speed, high precision, high efficiency,cost-effective and energy saving. It is the first choice of the metal processingindustry.

Model | 1330 | 1530 |

Laser Power | 300W/500W750W/1000W/1500W | |

Laser Source | Raycus or IPG Laser Fiber Laser Source | |

Laser Type | Imported Fiber Laser or Top Brand China Fiber Laser | |

Laser Technology | Germany Technology | |

XYZ Working area | 1300*2500*150mm | 1500*3000*150mm |

Max. Cutting Thickness (CS) | 1mm - 15mm | |

Max. Cutting Speed | 5-15 Meters / Min (up to materials) | |

Max. Location speed | 60m/min | |

Laser wavelength | 1070nm | |

Minimum line width | ≤0.1mm | |

Location precision | ≤±0.05mm | |

Re-location precision | ±0.02mm | |

Max. moving speed | 100m/min | |

Supporting Format | PLT, DXF, BMP, AI | |

Power demand | 380V/50Hz | |

Cooling Way | Water Cooling | |

Worktable max. load | 1000KGS | |

Transmission Method | Ball Screw Transmission | |

Table-driven system | Japanese Imported Servo Motor & Driving System | |

Focus Method | Following and Automatic Adjust Focus | |

Control software | Perfect Laser Professional Laser Cutting Software | |

Key word | 1.5kw fiber laser cutting machine | |

advantages:CNC Fiber Laser Cutting Machine

1.Excellent Laser Beam Quality: Fiber laser has smaller focus diameter and high work efficiency, high accuracy and cutting quality.

2.High Cutting Speed: cutting speed is more than 20M/min.

3.Stable Running: adopting the top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4.High Efficiency for Photoelectric Conversion : Compare with CO2 laser cutting machine ,fiber laser cutting machine have 3 times photoelectric conversion efficiency.

5.Low Cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%.Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

6.Free of Maintenance: Fiber optical transmission, fiber line transmission, no need reflect lens, without optical adjustment, save maintenance cost.

7.Easy Operations: fiber line transmission, no adjustment of optical path;

8.Super Flexible Optical Effects: compact design, compact and easy to flexible manufacturing requirements.