Specifications

Cutting Speed:30000mm/min max

Graphic Format Supported:AI, BMP, DST, DXF, PLT

Application:Laser Cutting

Condition:New

Cutting Thickness:Depends

CNC or Not:Yes

Cooling Mode:Water Cooling

Control Software:Lasercut

Place of Origin:Anhui, China (Mainland)

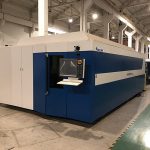

Model Number:FC-403CG

Certification:CCC, CE, ISO

Working area:4000*300*300mm

X/Y Positioning Accuracy:±0.02mm

Z Positioning Accuracy:±0.008mm

X/Y Repeat Accuracy:±0.015mm

Laser type:Fiber laser

Laser power:500W-2000W

Max. Moving Speed:80m/min

X/Y Max. Acceleration:0.8G

Cooling mode:Water-cooling

After-sales Service Provided:Engineers available to service machinery overseas

Product Description

Product Application

It can cut metal rectangular pipe, round metal pipe, and tube shaped pipes and other profiles. Cutting, holing, punching, slop cutting, intersecting, lettering and carving functions can be achieve on various pipe through FC-403CG.

Application:

Mainly suitable for fitness equipment, home office, kitchen cabinet and other sectors of pipe.

Pipes: Regular pipe, rectangular pipe, shaped tubes and other profiles.

SPECIFICATIONS | |

Working area | 4000*300*300mm |

Laser power | 500W-20000W |

Cutting speed | 0-30m/min |

X/Y Positioning Accuracy | ±0.02mm |

Z Positioning Accuracy | ±0.008mm |

Laser type | Fiber laser |

Cooling mode | Water cooling |

X/Y Repeat Accuracy | ±0.015mm |

X/Y Max. Acceleration | 0.8G |

Workbench max loading weight | 4T |

Main Features

1. High light conversion rate, above 30%, much higher than CO2 and YAG

2. Energy saving, no auxiliary air is needed, save cost as well as electricity

3. Maintenance free, no optical adjustment needed before starting.

4. Wavelength is only 1/10 of Co2 laser, but with high watt density, very suitable on cutting metal.

5. Fiber optical cable transfer, stable and simple

6. Protective lens in the cutting head, can protect focus lens

How to make a FANCH?

● Everything is starting at making a sturdy machine bed. Using 12mm thickness steel slab, Fanch workers cutting it according to the designed size and seamless welding the structure.

● But that is not good enough to make the sturdy bed. The whole structure quenching at 600℃ is necessary to reduce the mutua repulsion between different steel structure parts.

● In order to get the light but firm gantry, Fanch apply one piece casting aluminum. Seamless make the gantry more stable during fast moving.

● ±0.05 mm deviation straightness of machine bed surface can be got by our Germany imported milling machine. This is the root base of working accuracy and long life service.

● Top brand spare parts further make sure the accuracy, stability and long life span of a Fanch machine.